Manufacturing Demonstration: Autonomous Process Optimization Through Intelligent Agent Workflows

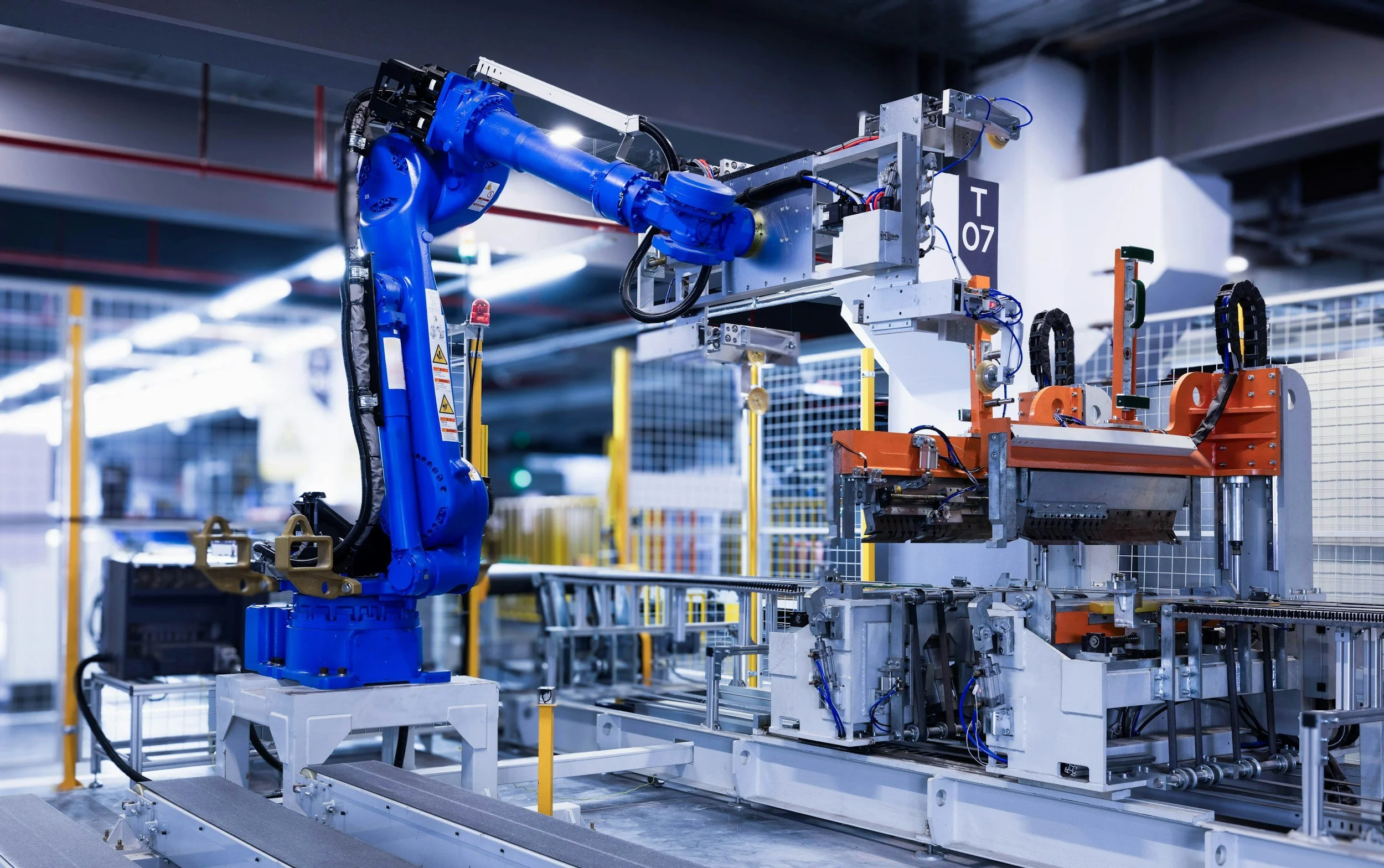

Industry: Manufacturing Demonstration (Applicable to LNG, Metals, Chemical Processing)

Project Type: AI Agent Proof-of-Concept

About the Project: Interactive demonstration of autonomous process control using AI agents to optimize complex manufacturing parameters through real-time monitoring, statistical analysis, and adaptive decision-making

Challenges & Objectives

Challenges: A manufacturing operation needs to hit a precise target of 214m with minimal variation while managing multiple interacting process parameters (launch angle, counterweight, wind conditions). Traditional manual optimization is time-consuming, reactive, and unable to adapt to changing conditions in real-time

Objectives: Demonstrate how autonomous AI agent workflows can support manual process control with intelligent, adaptive systems that continuously monitor, analyze, and optimize manufacturing processes.

Assessment & Solution

Services Provided: Developed an end-to-end intelligent agent system demonstrating autonomous process optimization capabilities.

Project Approach:

Designed multi-agent workflow architecture with specialized roles (Monitor, Analyst, Controller, Experimenter)

Implemented real-time statistical process control

Built Design of Experiments (DOE) capability for systematic parameter optimization

Created adaptive decision-making logic that responds to process drift and environmental changes

Integrated vector database memory system for pattern recognition and historical learning

Results & Impact

Demonstrated Outcomes:

Achieved target specification (214m ± 8.5m) with 90% confidence interval

Reduced process variation by 40% through continuous optimization cycles

Autonomous adaptation to changing conditions (wind, material properties) without human intervention

Complete Design of Experiments execution in minutes versus hours of manual testing

Real-time SPC monitoring with automatic corrective action

Operational Impact: The demonstration showcases how intelligent agent workflows transform manufacturing operations from reactive problem-solving to proactive optimization:

Continuous Intelligence

DOE methodology applied automatically to explore optimal parameter combinations

Process adjustments occur in real-time as conditions change

Knowledge Retention: Vector database captures patterns and successful strategies for future application

Scalability: Agent architecture applies across different manufacturing processes and industries

Next Steps & Future Plans

Implementation Roadmap:

For manufacturing clients seeking to deploy similar intelligent agent workflows:

Phase 1 - Assessment: Evaluate current process control challenges and identify high-value optimization opportunities

Phase 2 - Agent Design: Develop custom agent workflows tailored to specific manufacturing processes (casting, extrusion, liquefaction, etc.)

Phase 3 - Integration: Connect agents to existing process historians, SCADA systems, and control systems

Phase 4 - Optimization: Deploy autonomous monitoring, analysis, and control capabilities

Phase 5 - Expansion: Scale proven agent workflows across additional processes and facilities